Packaging Insights

The Printing Process

The most important thing in the printing process is to confirm the special process of the box shape and logo. This involves detailed planning and precise execution to ensure the final product meets the desired specifications. The printing process consists of several stages, each crucial in achieving high-quality results.

1. Design and Prepress

The journey begins with the design phase, where the artwork and structural design of the packaging are created. This stage is collaborative, often involving graphic designers, packaging engineers, and marketing professionals. The goal is to develop a design that is both visually appealing and functional.

Once the design is finalized, it moves to the prepress stage. Here, the digital files are prepared for printing. This includes checking for errors, adjusting colors, and ensuring that the layout fits the printing specifications. Prepress technicians create proofs, which are reviewed and approved before moving forward. This step is vital to catch any issues early and to ensure that the design translates well from screen to print.

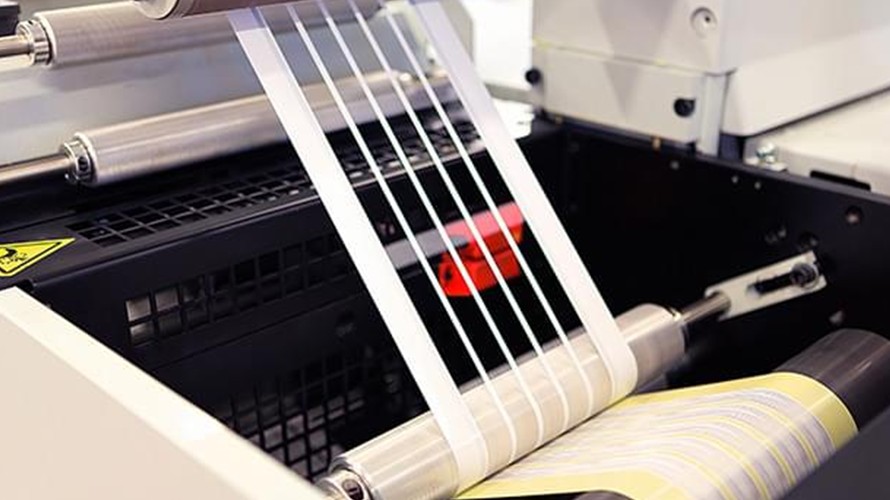

2. Choosing the Printing Method

The choice of printing method depends on various factors, including the type of material, the complexity of the design, and the production volume. The most common printing methods used in packaging include:

Offset Printing: Known for its high-quality output, offset printing is ideal for producing sharp images and vibrant colors. It is commonly used for large print runs of paper-based packaging.

Flexography: This method is well-suited for printing on flexible materials like plastic, foil, and corrugated cardboard. Flexography uses flexible plates and fast-drying inks, making it efficient for high-volume production.

Digital Printing: Digital printing offers flexibility and quick turnaround times, making it perfect for short runs and customized packaging. It allows for direct printing from digital files, eliminating the need for plates.

Screen Printing: Often used for specialty effects and smaller runs, screen printing is ideal for printing on unconventional materials or adding unique textures and finishes.

3. Printing

With the design approved and the method chosen, the actual printing begins. The selected materials are loaded into the printing press, and the process of transferring ink to the substrate starts. Precision is key during this stage to maintain consistency and quality across all units. Operators monitor the process closely, making adjustments as needed to ensure color accuracy and print alignment.

4. Special Processes and Finishing

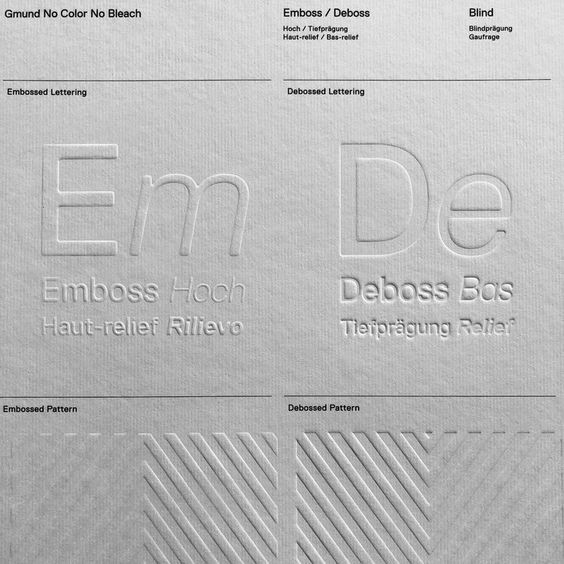

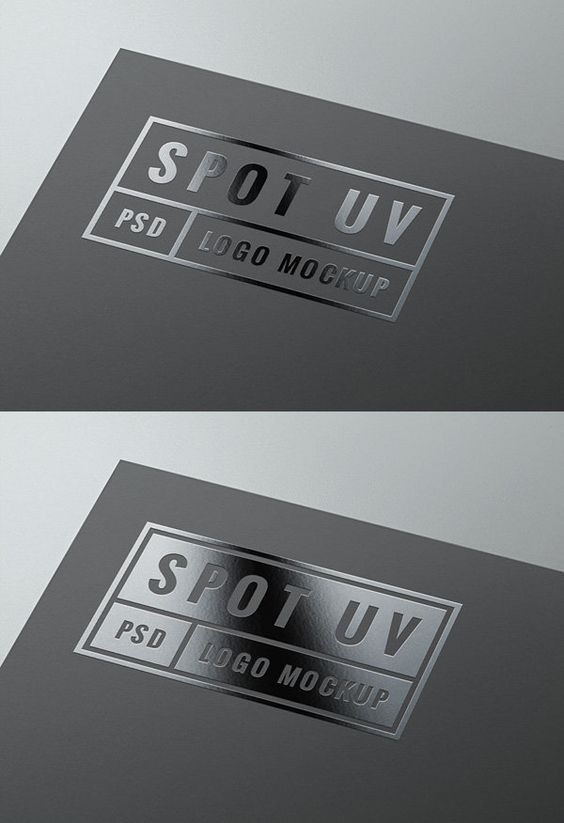

One of the defining aspects of high-end packaging is the special processes and finishing techniques applied after the primary printing. These processes add both aesthetic appeal and functional benefits. Some common finishing techniques include:

Foil Stamping: This involves applying a metallic foil to specific areas of the design, creating a luxurious and eye-catching effect. Foil stamping is often used for logos and brand names.

Embossing and Debossing: These techniques create raised or recessed designs on the surface of the packaging, adding texture and depth. Embossing and debossing are popular for highlighting logos and patterns.

Spot UV Coating: This process applies a glossy finish to specific areas of the print, enhancing contrast and adding a premium feel. Spot UV coating is frequently used to highlight images or text.

Die-Cutting: Die-cutting is used to create custom shapes and intricate designs in the packaging material. This technique is essential for producing unique box shapes and window displays.

5. Quality Control

Quality control is an integral part of the printing process. At various stages, inspections are conducted to ensure that the printed materials meet the required standards. This includes checking for color consistency, print clarity, and the accuracy of special processes. Any defects or deviations are addressed promptly to maintain the integrity of the final product.

6. Assembly and Packaging

Once the printed materials have passed quality control, they are assembled into their final form. This may involve folding, gluing, and combining different components. The finished products are then packed and prepared for shipping. Proper packaging ensures that the items are protected during transit and reach their destination in pristine condition.

Conclusion

The printing process is a complex and meticulous journey that transforms creative ideas into tangible products. By confirming the special processes of box shapes and logos, and carefully executing each step, the printing industry continues to produce high-quality packaging that stands out in the market. The attention to detail and dedication to excellence are what make the printing process a critical component in the success of any packaging project.